ABOUT Wetech

ABOUT Wetech

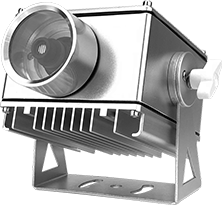

Wireless Taillift Safety Warning Light

The Taillift Safety Warning Light is a specialized safety lighting device designed for vehicles equipped with a rear-mounted lifting system (tail lift). Its primary function is to visually warn nearby pedestrians, cyclists, and other drivers when the tail lift is in operation—either when it is being deployed, in use, or retracted. The warning light is typically installed on the rear of the vehicle, often near the tail lift, and activates automatically when the lift is engaged. It projects a highly visible pattern (usually a red or amber light) onto the ground behind and around the vehicle, creating a clear “danger zone” or “safety boundary” that indicates the area where the lift is moving or where goods are being loaded/unloaded.

Enhanced Safety:

Clearly marks the hazard area in real-time, reducing the risk of accidents involving people or objects near the moving tail lift.

Improves visibility in low-light conditions (e.g., early morning, dusk, or poorly lit loading areas).

Accident Prevention:

Helps prevent collisions, entrapment, or trips and falls by alerting individuals to stay clear of the operational zone.

Particularly crucial in busy urban environments, warehouses, or congested loading docks where distractions are common.

Compliance & Liability Reduction:

Meets workplace safety regulations and vehicle safety standards in many regions, promoting legal and operational compliance.

May reduce the risk of liability claims by demonstrating proactive safety measures.

Automatic Operation:

Often integrates with the tail lift’s hydraulic or electrical system, activating automatically when the lift is used—no manual switch required.

Ensures consistent safety practices without relying on operator intervention.

Durability & Reliability:

Built to withstand harsh environments (weather, vibration, impact) common in logistics and transport operations.

Low maintenance and long-lasting, often using LED technology for energy efficiency and bright illumination.

Clear Communication:

Provides an intuitive, universally understood visual warning, overcoming language barriers or noise in loud work environments.

Operational Efficiency:

By improving safety, it helps avoid delays caused by accidents or injuries, keeping loading/unloading processes smooth and efficient.

View More

Our Products

Our Products

About Us

About Us

Our Advantages

Our Advantages

Our Blog

Our Blog